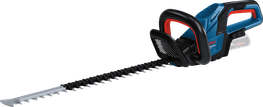

We offer cordless drill/drivers in the 12 V class and the 18 V class. The tools from the 12 V class use rechargeable batteries from our and boast a compact design, which makes them ideal for work in confined areas. Despite their compact design, our cordless screwdrivers from the 12 V class provide high power up to a torque of 35 Nm.

Our 18 V cordless drill/drivers are part of our and particularly impress users with their power, robust design and handling. The tools' power ranges from 21 Nm to the 150 Nm (maximum torque) generated by our GSR 18V-150 C. This means that you can use our drill/drivers for a range of work, from simple assembly work to the toughest tasks in woodwork. Many of our models are fitted with a metal drill chuck to ensure that our tools can endure even the toughest applications. Another special feature is our KickBack Control, which is also incorporated in many of our models.

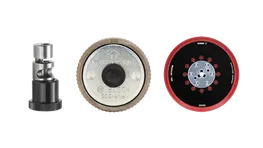

A further highlight is our FlexiClick system: In both the 12 V and 18 V categories, we offer tools on which you can quickly and simply replace the drill chuck with other attachments, such as an angle drill head or off-set angle adapter. In the case of the you can even turn your cordless screwdriver into a rotary hammer by attaching the GFA 18-H hammer attachment.

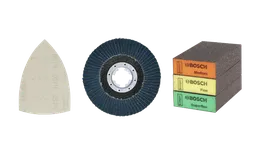

You can find a large selection of suitable accessories, such as bits and bit sets, in our .