Accuracy Check of the Measuring Tool

The largest influence is exerted by the ambient temperature. In particular, temperature differences that occur from the ground upwards can refract the laser beam.

In order to minimise thermal influences resulting from heat rising from the floor, it is recommended that you use the measuring tool on a tripod. In addition, position the measuring tool in the centre of the work surface, wherever this is possible.

In addition to external influences, device-specific influences (e.g. falls or heavy impacts) can also lead to deviations. For this reason, check the levelling accuracy each time before beginning work.

First check the levelling accuracy of the horizontal laser line, then the levelling accuracy of the vertical laser lines.

Should the measuring tool exceed the maximum deviation during one of the tests, please have it repaired by a Bosch after-sales service.

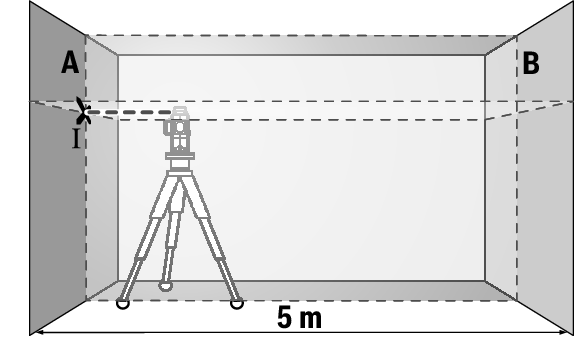

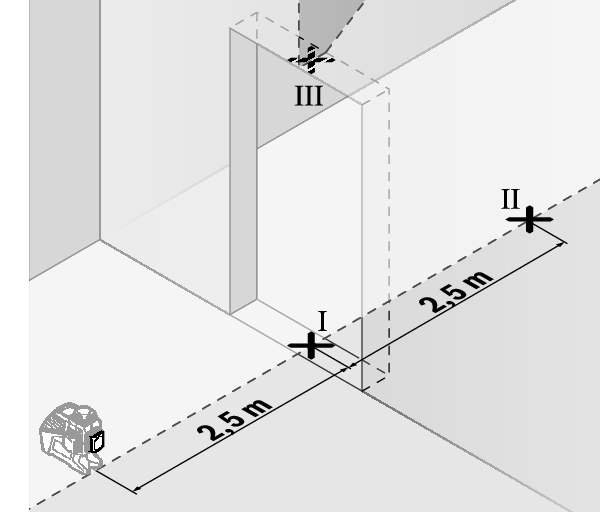

For this check, you will need a free measuring distance of 5 m on firm ground between two walls (designated A and B).

- Mount the measuring tool close to wall A on a tripod, or place it on a firm, flat surface. Switch on the measuring tool in the mode with automatic levelling. Select the operating mode for generating a horizontal laser plane and a vertical laser plane directly in front of the measuring tool.

- Aim the laser at the closer wall A and allow the measuring tool to level in. Mark the middle of the point at which the laser lines cross on the wall (point I).

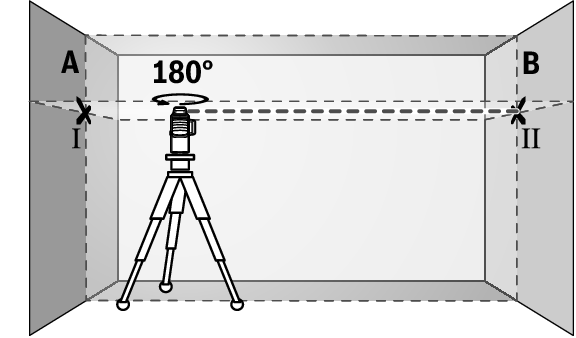

- Turn the measuring tool 180°, allow it to level in and mark the point where the laser lines cross on the opposite wall B (point Ⅱ).

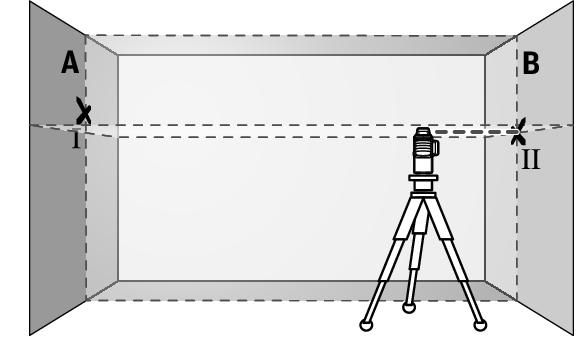

- Position the measuring tool – without rotating it – close to wall B, switch it on and allow it to level in.

- Align the height of the measuring tool (using the tripod or by placing objects underneath as required) so that the point where the laser lines cross exactly hits the previously marked point Ⅱ on wall B.

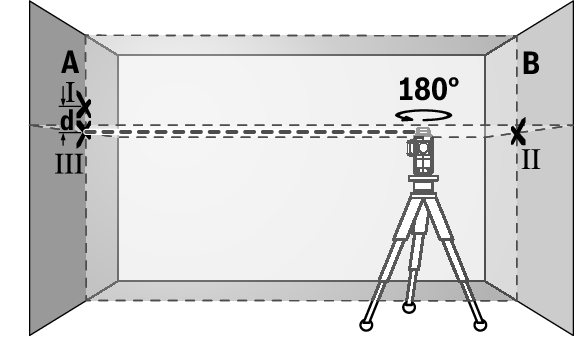

- Turn the measuring tool 180° without adjusting the height. Aim it at wall A such that the vertical laser line runs through the already marked point Ⅰ. Allow the measuring tool to level in and mark the point where the laser lines cross on wall A (point Ⅲ).

- The discrepancy d between the two marked points Ⅰ and Ⅲ on wall A reveals the actual height deviation of the measuring tool.

The maximum permitted deviation on the measuring distance of 2 × 5 m = 10 m is as follows:

10 m × ±0.2 mm/m = ±2 mm. The discrepancy d between points Ⅰ and Ⅲ must therefore amount to no more than 2 mm.

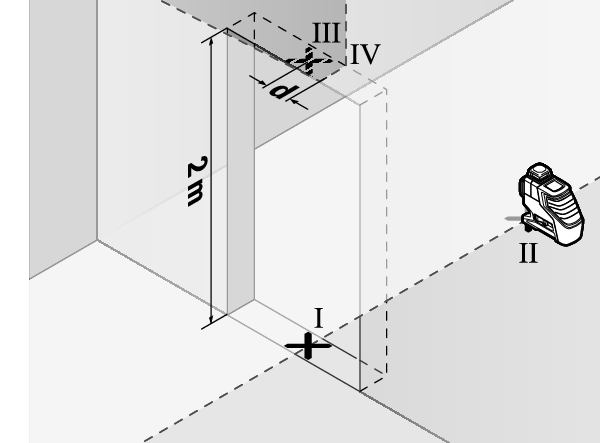

For this check, you will need a door opening (on solid ground) which has at least 2.5 m of space either side of the door.

- Place the measuring tool 2.5 m away from the door opening on a firm, flat surface (not on a tripod). Switch on the measuring tool in the mode with automatic levelling. Select the operating mode for generating a vertical laser plane directly in front of the measuring tool.

- Mark the centre of the vertical laser line on the floor of the door opening (point Ⅰ), 5 m away on the other side of the door opening (point Ⅱ) and on the upper edge of the door opening (point Ⅲ).

- Rotate the measuring tool 180° and position it on the other side of the door opening, directly behind point Ⅱ. Allow the measuring tool to level in and align the vertical laser line in such a way that its centre passes through points Ⅰ and Ⅱ exactly.

- Mark the centre of the laser line on the upper edge of the door opening as point Ⅳ.

- The discrepancy d between the two marked points Ⅲ and Ⅳ reveals the actual vertical deviation of the measuring tool.

- Measure the height of the door opening.

Repeat the measuring process for the two vertical laser planes. To do this, select the operating mode for generating a vertical laser plane to one side of the measuring tool and rotate the measuring tool by 90° before beginning the measuring process.

You can calculate the maximum permitted deviation as follows:

Doubled height of the door opening × 0.2 mm/m

Example: At a door opening height of 2 m, the maximum deviation amounts to

2 × 2 m × ±0.2 mm/m = ±0.8 mm. The points Ⅲ and Ⅳ must therefore be no further than 0.8 mm from each other.