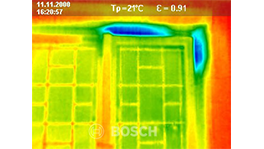

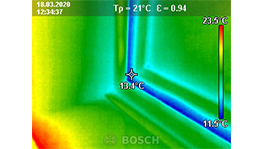

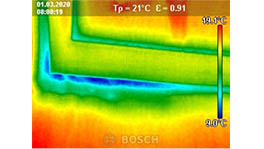

On the one hand, they help you to look "behind the scenes" and quickly find weak points in windows and doors – in other words, they allow you to directly identify and rectify thermal bridges caused by insulation faults or areas that are not leak-tight. On the other, you can also make use of the thermal images to prove you have done a good job – when installing or performing maintenance on windows, for example – and impress the customer with a before-and-after comparison.

The correct installation of windows and doors is not only important for maintaining the indoor climate, but also for energy efficiency, which is increasingly gaining significance among customers. With regard to this, the Bosch temperature measuring tools are also particularly useful when it comes to providing advice and consultation on energy-oriented refurbishment: Window construction can be time-consuming and expensive, and without clear evidence of what needs to be done, many customers would likely adopt a "wait-and-see" approach instead. Thanks to the thermal imaging cameras and the infrared thermometer from Bosch, you can take stock of the situation with a thorough overview and make any energy leaks that may be present clearly visible, such as those at sky lights or dormers. This means that you can plainly see where there is a need for new windows.

.png

)

.png

)