Wood routers come in different types to suit various woodworking tasks. Each type offers unique features that make them perfect for specific jobs in the workshop.

Your selection is

Your selection is being processed

Types of Wood Routers

Fixed Base Routers

Fixed base routers stand as workhorses in any professional woodworking shop. We've seen these tools transform raw timber into masterpieces through their stable and precise operation.

They excel at creating straight edges, perfect grooves, and decorative profiles that elevate your projects. The consistent depth adjustment ensures your cuts remain uniform throughout the entire workpiece - a crucial feature when working on cabinetry or detailed trim work.

The right fixed base router becomes an extension of your craftsmanship, allowing precision that simply can't be achieved with other tools.

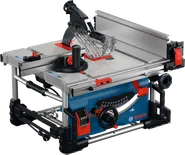

Our Bosch fixed base routers combine power with user-friendly features that boost both safety and efficiency. Many models offer variable speed settings to match your specific material needs.

The ¼" or ½" collets accept a wide range of router bits, giving you versatility for different woodworking tasks. Most professionals find these tools ideal for router table mounting, which adds another dimension to your woodworking capabilities.

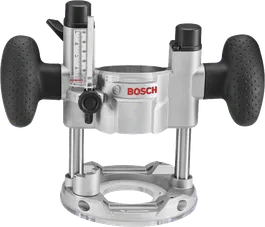

Plunge Routers

Plunge routers offer exceptional versatility for woodworking tasks that require starting cuts in the middle of a workpiece. These powerful tools feature a spring-loaded base that lets you "plunge" the bit straight down into your material.

We find plunge routers ideal for cutting mortises, creating decorative inlays, and making stopped dados. The depth adjustment on these models allows for precise control, with most units featuring depth stops for repeatable cuts at exact measurements.

Many professionals prefer the 18V cordless options for job site flexibility, though corded models still deliver higher rpm for demanding cuts.

Our customers often choose plunge base routers for complex joinery work like dovetails and mortise and tenon joints. The plunge action makes it safer to lower the bit into the wood at your marked position rather than entering from the edge.

Most quality models now come with variable-speed controls (8,000-24,000 rpm) to match the right speed to your material and bit size. For maximum control, look for models with soft-start features and ergonomic handles that reduce hand fatigue during extended use.

Trim Routers

Trim routers offer a compact and lightweight option for detail work in woodworking projects. These small but mighty tools excel at edge forming, laminate trimming, and creating decorative profiles in tight spaces.

We find trim routers particularly useful for jobs where larger routers might be too bulky or powerful. Most trim routers feature a 1/4-inch collet size and operate between 16,000-30,000 RPM, giving professionals precise control for intricate tasks.

Our professional customers often choose cordless trim routers for their portability on job sites. The brushless motor options provide longer runtime and less maintenance, making them ideal for busy tradespeople.

Many models from top brands like Makita and DeWalt now include variable speed settings, soft-start features, and ergonomic grips that reduce hand fatigue during extended use. For edge work, hinge installation, and small joinery tasks, a quality trim router belongs in every woodworker's tool collection.

Choosing the Right Router for Your Project

Selecting the perfect router for your woodworking needs starts with understanding your project requirements. Fixed base routers offer stability for edge work and precise depth control, making them ideal for tasks like trimming laminates or creating decorative edges.

Plunge routers excel at starting cuts in the middle of workpieces - perfect for mortises, inlays, and dadoes. For small detail work, a compact palm router provides the control and maneuverability needed for intricate designs.

Power output matters too - professionals tackling hardwoods should look for models with at least 2HP, while lighter tasks may only need 1-1.5HP.

Router bit compatibility should guide your choice as well. Most professional-grade routers accept both ¼-inch and ½-inch shank bits, with the latter offering more stability for heavy-duty cutting.

We suggest models with variable speed controls (8,000-24,000 RPM) to match the right speed to different materials and bit sizes. Comfort features like ergonomic handles, dust collection ports, and soft-start motors reduce fatigue during long jobs.

For maximum versatility, some professionals invest in a router combo kit that includes both fixed and plunge bases with a single motor unit - this provides flexibility across various projects without doubling your tool investment.

Essential Tips for Using a Wood Router

Our guide shares key tips for using a wood router safely and effectively, from proper speed settings to choosing the right router bits for your woodworking projects - read on to master this versatile tool!

Safety Precautions

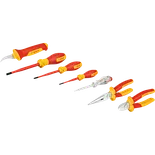

Safety must come first when using a router tool. We always wear eye protection, ear defenders, and dust masks to guard against flying debris and harmful dust. A good pair of gloves will protect your hands, but make sure they fit well to maintain proper control of the tool.

Secure your workpiece with clamps before starting - a shifting piece can cause serious accidents. Our dust extraction solutions help keep your workspace clean and reduce health risks from fine wood particles.

The power switch should be easy to reach at all times. We recommend unplugging your router when changing bits or making adjustments. Sharp router bits cut better and reduce kickback risks.

Keep both hands on the router handles during operation for maximum control. The router should move against the bit rotation - going with the rotation can cause the tool to jerk forward unexpectedly.

These simple steps make woodworking safer for trade professionals on every job site.

Proper Speed Settings

Beyond keeping safe, setting the right speed on your router makes a huge impact on your work. Most routers come with variable speed controls that range from 8,000 to 30,000 RPM. We suggest starting at lower speeds for larger bits (over 1 inch) to reduce the risk of burning the wood or damaging your tool.

For smaller bits, higher speeds often yield cleaner cuts in hardwoods like oak or maple. The material you're working with matters too - softer woods allow faster speeds, while harder woods and plastics need slower approaches.

The perfect router speed balances efficiency and control - too fast burns the wood, too slow leaves rough edges. Find that sweet spot for each project.

Speed adjustments also depend on the task at hand. Edge profiling works best at medium speeds around 16,000-20,000 RPM, giving you better control. Deep cuts should be made in multiple passes, gradually increasing depth rather than forcing the router through at high speed.

Our professional-grade routers feature electronic speed control that maintains consistent RPM even under load, ensuring smooth, clean cuts every time.

Using the Correct Router Bits

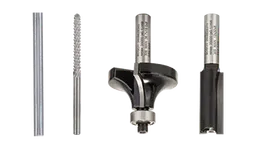

Selecting the right router bits makes all the difference in your woodworking projects. We recommend starting with basic bits like straight, roundover, and chamfer bits for most tasks.

The bit shank diameter matters too - ½ inch shanks offer more stability than ¼ inch options, especially for heavy-duty work. Our professional tip is to match your bit type to your specific task - use spiral bits for clean plunge cuts and flush trim bits for laminate work.

Router bits come in various materials that affect both performance and price. High-speed steel bits work for occasional use, while carbide-tipped bits last longer for daily professional tasks.

Bits spin at high speeds, so keep them clean and sharp to avoid burns on your wood pieces. We suggest storing your bits in protective cases to prevent damage to the cutting edges and extend their useful life.

Conclusion

Wood routers stand as vital tools for any woodworking project. We've covered the key types, safety tips, and best practices to help you master this power tool. With the right router bits and proper speed settings, you'll create stunning edges and joints in your lumber.

Your skills will grow with each project as you apply these router techniques. Practice makes perfect - start with simple cuts before moving to complex designs on your router table.

* You can find more information about the deviations in the following link: