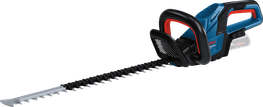

It will take seven years to build the . And it will take seven seconds to cross it. One of the most anticipated construction projects in Germany, the Filstal Bridge (or "Filstalbrücke" in German) is a new high-speed ICE railway bridge that stands 85m tall and stretches 500m across the Fils Valley. Due to its unique tunnel-bridge-tunnel design, the construction has been pushing architecture, engineering, and power tools to new heights. To make tough work easier, we gave the builders of the Filstal Bridge our latest 18V cordless angle grinders with .

Building at new heights is tough work – but it's easier with Bosch Professional.