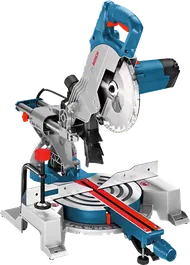

Ideal for large-scale cutting demands, mitre saws offer improved efficiency and flexibility while cutting timber, plastic, and aluminium. Large and powerful mitre saws are a staple of woodworking sites, and the Bosch catalogue has a wide range of models to help you enhance your work.

Your selection is

Your selection is being processed

Mitre Saws With Superior Cutting Performance

Mitre Saw Features

Our mitre saws are that provide exceptional cutting performance with large circular saw blades. They utilise a range of innovative features to improve your efficiency and safety at work, including:

- BITURBO Technology: Our range of 18V cordless mitre saws use advanced brushless motor technology that reduces the wear on the motor and improves durability, helping you produce precise cuts for longer.

- Dual Laser: Bosch mitre saws use two lasers for high-precision cutting. They project onto the material on the left and right sides of the cutting line, helping improve your accuracy while sawing.

- Dust Extraction Ready: Our mitre saws allow you to attach a vacuum or dust extractor directly to the tool. This keeps your workplace clean from dust and debris, helping you work more safely and efficiently.

Popular Mitre Saw Models

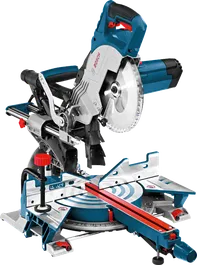

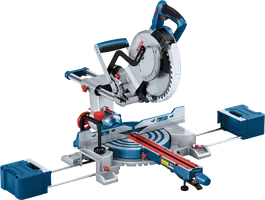

Mitre saws vary in size and shape. Different types of mitre saws include sliding, compound, combination, and cordless varieties that all offer distinct properties and advantages. The Bosch catalogue has many high-performance mitre saws, including:

- : This sliding mitre saw is light and compact, ideal for tradespeople that are always on the move or have limited space. Its saw blade has a diameter of 216 mm and rotates at a speed of 5,500 rpm.

- : With Bosch’s patented glide arm design, this model provides incredibly high-precision cutting. Its double line laser, robust sliding mechanisms, and high-quality saw blade enhance the accuracy and efficiency of your cuts.

- : This cordless mitre saw uses BITURBO technology to provide 5,000 rpm of rotation speed and a cutting capacity of 70 x 305 mm at 0°. With dual lasers and a built-in dust extraction system, this model is ideal for a range of sawing applications.

Versatile Mitre Saws for All Jobs

Operated on a workbench or tabletop, mitre saws are ideal for making angled cuts through all kinds of materials, including wood, plastic, aluminium, laminate, PVC, fibre cement, and plasterboard. As a result, they’re well-suited to many tradespeople, from carpenters to electricians to construction workers.

Mitre saws are especially suited to jobs with demanding cutting requirements, as their high-powered saw blades are well-adapted to intense cutting tasks. These types of saws cover cutting capacities from 70 x 270 mm to 104 x 341 mm, with some models even reaching beyond this range when a spacer is attached.

Additionally, saw blade diameters can reach up to 305 mm in the larger models. Most models have 47° bevel angle both right and left, while the mitre setting ranges from 47° to 60°, which provides enhanced cutting depth and capabilities and makes the mitre saw a highly versatile tool.

As with any power tool, mitre chop saws carry risks. However, Bosch saws are designed with innovative safety features to reduce the potential for workplace injuries. Dust extraction systems keep your space clean while our Soft Start feature gradually accelerates the tool so you can operate and manoeuvre it more easily.

Why Buy Direct from Bosch?

Our power tools are designed for tradespeople in all types of jobs. When you buy directly from Bosch, you can guarantee quality, safety, and support in your work. Here are just some of the benefits of purchasing through Bosch:

- Professional Support: Your specialist queries need specialist answers. Our customer support team are readily available to provide technical solutions and guidance, helping you maximise your productivity and safety while you work.

- Exclusive Offers: With up to 3 years of warranty on power tools and accessories, plus free shipping to the UK on orders over £50, you can save money on guaranteed quality by buying through Bosch.

- Premium Quality Tools: Bosch has been a trusted manufacturer of professional-grade power tools for decades. We strive to provide the best quality and safety in all our tools, so you know you’re getting the highest standards when you buy from Bosch.

Choose Bosch for Your Mitre Saws

Bosch mitre saws offer unparalleled reliability in the workplace thanks to their improved cutting performance, dual lasers for high precision, and safety features for efficient work. We guarantee the best quality and safety of our tools, offering you exclusive warranties and professional support should you need it. Buy Bosch mitre saws and stands today.

* You can find more information about the deviations in the following link: